Well, this Saturday I spen the better of 3 hours rewiring my engine harness and I have to say it wasn't the difficult. With the use of the proper tools, the right connectors, and the Volvo electrical manual has made the job fairly easy.

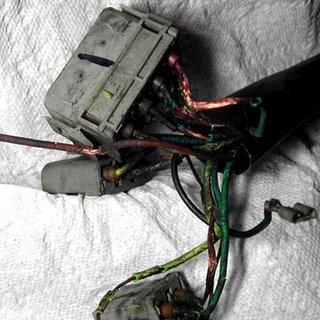

The process began by carefully removing the dry and brittle heat sheild so as no to damage the wires. This was similar to cracking the shells on crab legs! The stuff was so dry and brittle that on occasions I thought I cut my fingers several times. But taking my time I got all the stuff off.

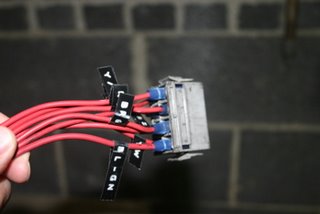

I then proceeded to replace each wire individually making sure the connectors were correct and placed back in it's right spot. By doing it this way I was guaranteed the right length of wire, the connectors, and it's placement. It's mind numbing process but great mediation! Afterwards I tried to recall what I was thinking about during the project but realized my mind was a total blank!

Suggestions to anyone who would attempt this is to make sure you have an assortment of connectors, correct wire gauge, and patience. I'll post some pictures in a little while.